Specialised Conveying

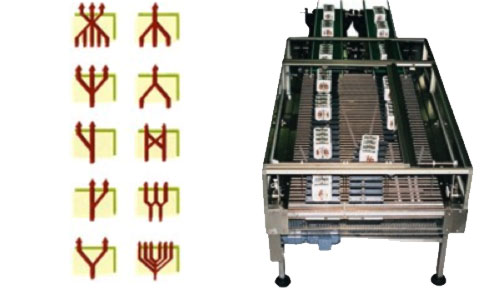

Slat dividers & Combiners

Prime Engineering Services offers the full range of LM group specialist conveying & handling systems.

The LM group is a leading European manufacturer of unique product & material handling equipment & systems for a broad range of products & markets.

The LM slat dividers & combiners provide high speed, continuous motion, sort or merge of conveyed products.

Typical applications for LM dividers & combiners include:

- Sort or collate to different lanes based on the signal from upstream device or devices such as check weighers, metal detectors, bar code readers, vision systems etc.

- Balance of product flow to downstream machines

- Connection between different numbers of machines to downstream machines with different capacities.

- Optimising freezing, cooling or cooking tunnel conveyors by side shifting product as needed to fill unused areas of belting.

- Layer preparation for palletising or secondary packaging

Dividers D8

Compact size, low noise, easy connection with upstream and downstream conveyors and competitive pricing are but a few of the main features of this model of Divider.

Product conveying examples include:

- Non-packaged products (snacks, bakery products, frozen products)

- Thermoformed trays

- Cardboard, plastic, polystyrene trays

- Flexible packaging by Vertical and horizontal wrappers

Special features:

- Maximum speed (m / min): 60

- Maximum Number switches (per minute): 200

- Small footprint

- Available in 3 types of construction: painted steel, stainless steel, stainless steel - wash down

- Easy maintenance

- Several standard systems to facilitate the inlet and outlet transfers (also with unstable products)

All LM Dividers can be configured as a Divider, Combiner, or Combiner/Divider, subject to the parameters of the specific application.

Dividers D12/D16

High performance both in terms of speed and number of switching per minute in combination several configurations of inlets and outlets, makes model D12/16 the most sold type of divider within LM production range.

Suitable for:

- Non-packaged products (snacks, bakery products, frozen products)

- Thermoformed trays

- Cardboard, plastic, polystyrene trays

- Flexible packages by vertical and horizontal wrappers

- Shrink wraps

- Carton boxes (American cartons, wraparound, cluster pack, etc.)

Special features:

- Maximum speed (m / min): 120

- Maximum Number of switching (per minute): 400

- Low noise operation

- 3 executions: painted steel, stainless steel, wash down

- Easy maintenance

- Several standard systems to facilitate the loading and unloading of unstable products

Dividers D25

Very robust construction and a number of standard width's and length's, allow handling a large number of in-feeds and discharges, makes the Model D25 the most commonly used divider for all end-of-line needs particularly with Food/Beverage, and Warehousing/Logistics.

Suitable for:

- Carton boxes (American cartons, wraparound, cluster pack, etc.)

- Plastic crates/totes

- heavy products

Special features:

- Maximum speed (m / min): 80

- Maximum Number of switches (per line, per minute): 200

- Two versions: painted steel, stainless steel

- Easy maintenance

- Several systems to facilitate the loading and unloading of unstable products

All LM Dividers can be manufactured as a Divider, Combiner, or Combiner/Divider, subject to the parameters of the specific application